1.Background

With the development of power industry, the safety and reliability of equipment are highly demanding. In the past, the method of manual inspection equipment has been gradually weakened, under this condition, the wireless temperature measurement system of high voltage equipment came into being. This technology is to install the temperature sensor with built-in battery and wireless transmitting module at each temperature measuring point. Because of its small size and no connection, its electrical safety can be guaranteed. The sensor periodically sends the temperature measurement data wirelessly to the receiver, and it can send the data to the main station on a network, so as to realize the electrical temperature monitoring of a regional system.

Currently, many power grid companies, substations and steel companies in China have adopted this wireless temperature monitoring technology on high voltage equipment.

The electric terminal on-line temperature measuring device is using for the temperature monitoring of cable connector, circuit breaker contact, knife switch, high voltage cable intermediate head, dry transformer, low voltage high current and other equipment in high and low voltage switch gear.To prevent excessive contact resistance caused by oxidation, loosening, dust and other factors during operation, heating becomes a hidden danger of safety, to improve the safety and security of equipment, to reflect the running state of equipment in time, continuously and accurately, and to reduce the accident rate of equipment.

2.Project Brief

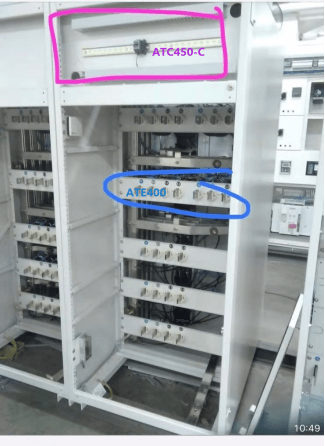

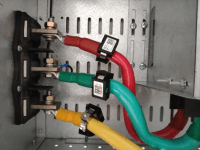

Hong Kong UNS is an smart power service company, providing intelligent energy solutions and distribution maintenance services for all kinds of commercial buildings. The project has 11kV of switchgear need to detect cable temperature, customers consult Acrel wireless temperature measurement products, attending through Acrel ATE wireless temperature sensor and ATC receiver, the cable in the switchgear temperature detection, And through RS485 communication data transmission to the back platform for real-time monitoring, can effectively prevent overheating failure, affect the normal operation of equipment, avoid safety risks.

1.Temperature measuring instrument

1)Temperature sensor

a.Battery-powered wireless temperature sensor

a.sensor installed in a heating area that collects temperature and transmits it wirelessly.

There are currently four type wireless temperature sensors:

|

Name |

Shape |

Parameter instruction |

Installation |

|

32.4*32.4*16mm(length*width*high, aperture); -50℃~+125℃, Accuracy Class ±1℃, battery powered, life ≥5 years; 470MHz, open distance 150m. |

Magnetic absorption fixation |

||

|

62.4*32.4*16mm, φ13.5mm( length*width*high, aperture); -50℃~+125℃, Accuracy class ±1℃, battery powered, life ≥5 years; 470MHz, open distance 150m. |

Bolt fixing |

||

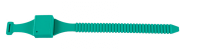

|

35*35*17mm, L=330mm ( length*width*high, belt); -50℃~+125℃, Accuracy Class ±1℃, battery powered, life ≥5 years; 470MHz, open distance 150m. |

strap binding

|

||

|

ATE100P |

|

62.4*32.4*16mm, φ13.5mm( length*width*high, aperture); -50℃~+125℃, Accuracy class ±0.5℃, battery powered, life ≥5 years; 470MHz, open distance 150m. IP68 |

Outdoor bolt fixing |

|

ATE200P |

|

35*35*17mm, L=330mm ( length*width*high, belt); -50℃~+125℃, Accuracy Class ±0.5℃, battery powered, life ≥5 years ; 470MHz, open distance 150m. IP68 |

Outdoor strap binding

|

b.CT induction radio wireless temperature sensor

b.sensor installed at a high current such as a circuit breaker contact, a bus bar, a cable lap contact, to collect temperature and transmit it wirelessly.

There are currently two wireless temperature sensors:

|

Name |

Shape |

Parameter Instruction |

Installation |

|

25.82*20.42*12.8mm(length*width*high); -50~+125℃, Accuracy class ±1℃, CT induction of electricity powered, starting current ≥5 A; 470MHz, open distance 150 m. |

Alloy sheet fixed and Powered |

c.Wired Temperature Sensor

c.Sensor installed in the contact of a high voltage cabinet, a transformer, or a motor winding to measure temperature, collect temperature and transmit it by wire.

Pt100 is wired temperature sensor at moment.

|

Name |

Shape |

Parameter Instruction |

Installation |

|

Pt100 |

|

Recommended self outsourcing For low voltage contact temperature measurement, specific packaging, accuracy, wire, wire length contact with suppliers; for transformer, motor winding temperature measurement, it is recommended that the transformer or motor internal embedded Pt100. |

Based on package decision |

2)Receiving /displaying unit

a.Receiving unit

|

Name |

Shape |

Parameter Instruction |

Installation |

|

65*45*28mm(length*width*high); DC24V power supply; RS485 interface along the way to receive 60 ATE400 wireless temperature sensor temperatures; Modbus protocol. |

35mm DIN rail screws fixed (φ4,36mm) |

||

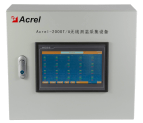

|

90*90*38mm( length*width*high); AC/DC 85~265V Power; 1 channel uplink RS485, Can receive 240 ATE wireless temperature sensor include ATE100/ATE100M/ATE200/ATE400/ATE100P/ATE200P; Modbus protocol. |

35mm DIN rail |

b.Displaying Unit

|

Name |

Shape |

Parameter Instruction |

Installation |

|

Panel 96*96*17mm, depth 65mm, cut-out size 92*92mm, AC85-265V or DC100-300V power supply; along the way line RS485 interface; can receive 60 ATE wireless temperature sensors include ATE100M/100/200/400/ATE100P/ATE200P (matching ATC450); Modbus protocol. |

Embedded panel installation |

||

|

ASD300/320 |

|

Panel 237.5*177.5*15.3mm, depth 67mm, cut-out size 220*165mm; AC85-265V or DC100-300V power supply; line RS485 interface along the way; can receive 12 wireless temperature sensors include: ATE100M/100/200/400(matching ATC450); Modbus protocol. |

Embedded panel installation |

|

ATP007 |

|

Panel 226.5*163*60mm, depth 70mm; hole 215*152mm; DC24V power supply; 1 channel uplink RS485 interface, 1 channel downlink RS485; can receive 4 ATC450-C or 1 ATC600.

|

Embedded panel installation |

|

Panel 96*96*12.5mm, depth 70mm, hole 88*88mm; along the way RS485 interface, can be connected to 8 channels of temperature sensor; Modbus protocol. |

Embedded panel installation |

||

|

Acrel-2000T/A |

|

The size of the cabinet is 480*420*200mm; DC220V power supply; 1 channel uplink RS485, the downlink is one Ethernet port, and 4 sets ATC450-C or 1 set ATC600 can be received |

Wall mounted |

|

Acrel-2000T/B |

|

The size of the cabinet is 480*420*200mm; Hardware: memory 4G, hard disk 128G, Ethernet port; displayer: 12 inches, resolution 800/600; operating system: Windows 7; database system: Microsoft SQL Server 2008 R2; I/O interfaces: GLAN×2, USB×4, COM×6; Optional Web platform/ APP server |

Wall mounted |

3.Recommended Customer Solution

a. Configuration solution: High and low voltage cabinet electrical contact wireless temperature measurement (without local display)

a.1 centralization(ATC450-C)

Instruction: ATC450-C wireless temperature transceiver can connect 60 wireless temperature sensors include ATE100/100M/200/400/100P/200P, support receive wireless temperature sensor temperature signals in multiple cabinets.

a.2(ATC600)

Instruction: ATC600 wireless temperature transceiver support connect 240 wireless temperature sensors include ATE100/100M/200/400/100P/200P, support receive wireless temperature sensor temperature signals in multiple cabinet with transparent transmission function.

b.Installation sample

Bibliography

1. Configuration of On-line Temperature Measurement Scheme for Electrical Terminal

2. The Application of Wireless Temperature Measuring Device in Low Voltage and Large Current Circuit Breaker

3. Solutions for enterprise micro-grid system