Abstract: The main function of protecting leakage equipment is to avoid direct or indirect contact with energized equipment, which is also a necessary measure for safe energization. As far as the basic requirements for electricity use on construction sites are concerned, the problems faced by the leakage protection equipment of the construction site when put into use are discussed, and improvements are made at the same time. This can effectively reduce the occurrence of accidents and is also an inevitable requirement for ensuring the smooth use of electricity during construction.

Keywords: leakage protection; construction site; electrical safety

0.Overview

The construction site is to use compulsory devices to protect the leakage equipment, the purpose is to ensure the safety of power supply at the construction site. In normal construction, due to the special construction site, the leakage protection device is often tripped, which not only hinders the construction process, but also endangers the safety of the construction site. Combining the actual situation of the construction site with the electricity usage, the phenomenon of frequent tripping of the leakage protection equipment at the construction site is summarized, and daily protective measures to protect the leakage equipment are given.

The main function of the protection of leakage equipment is to protect the energized equipment in the process of leakage or fatal danger when the human body gets an electric shock. The equipment is mainly composed of switches, experimental buttons, and disconnect devices, the overall structure of the disconnect, and residual current mutual inductance. It is composed of several parts such as a device. The grounding fault current of the protective equipment is between the leaking equipment that protects the leakage equipment, and when it exceeds the predetermined value, the main switch will automatically trip, and the fault current is cut off, which plays a protective role to a certain extent.

At the construction site, generally speaking, the electricity standards are not up to the requirements, and the facilities and lines put into use have many safety problems. The main characteristics are strong fluidity, multiple repetitions, and temporary nature.

1.Causes of Misoperation of Leakage Protector on Construction Site

1) External interference

a) The overvoltage caused by the positive and negative alternating process during lightning strikes, through overhead lines, insulated wires, cables and the ground capacitance of the electrical pen, generates ground leakage current, causing the residual current protector to malfunction or even directly damage. If it is too high, it will cause damage to the protector power supply and internal circuit, and the automatic switch trip coil with the loss-of-voltage release will burn out; The electromagnetic switch with mechanical locking device has insufficient power to absorb and jump, which makes the tripping speed slow or refuses to move.

b) In the process of lighting the construction site, the various lines laid and the electrical equipment put into use have been randomly built and constructed, which has caused the premature aging of the line, the reduction of the insulation resistance of the line and the energized facilities, and the current Leakage or even grounding has caused the leakage protection equipment to appear repeatedly and affect normal use. Because the insulation resistance of the line of the output terminal of the leakage switch is reduced and the grounding line is connected to the neutral line, the neutral point of the power supply is not grounded during the installation of the leakage protection device. In the process of electric shock, the sensitivity and refusal to move are reduced.

c) Environmental change interference. The most important factor here refers to environmental conditions, such as increased temperature in summer and warm and humid rainy season; or electrical facilities with strong amplitude installed around the leakage protection device; or long-term exposure during operation. The continuous corrosion and erosion of harmful gases; the insulation degree of the electromagnetic coil and composition structure of the electronic components of the leakage protection facility is reduced, mold breakage and rust appear, and eventually the leakage protection facility may act incorrectly or refuse to act.

2) The wiring of the leakage protector is wrong. When the leakage protector is installed, it is often caused by incorrect wiring or unsuitability of the installation method and circuit structure due to misoperation, refusal to move, or failure to achieve the best effect. After the neutral line passes through the leakage protector, it is connected with the neutral line of other leakage protectors or with other neutral lines that are not equipped with leakage protectors; the neutral line is broken or poorly connected, causing the neutral point to be biased. Shift the zero potential; these increase the probability of neutral line leakage and other failures.

3) The selection of the leakage protector is unreasonable. Protect leakage devices with a rated leakage current greater than 30mA or more than twice the standard current of the energized device, or choose a protective leakage device with a delay effect, because the rated leakage current continues to increase or the sensitivity is reduced, When the leakage accident occurs, the leakage protection equipment at the end is not operating, and the higher-level leakage protection equipment will start to operate.

4) The problem of the leakage protector itself

a) Inherent limitations. The current leakage protectors, whether electromagnetic or electronic, use magnetic induction transformers to pick up the leakage current in the main circuit of electrical equipment. It is impossible to arrange three-phase or three-phase four-wire in the magnetic ring to be completely balanced. For more two-phase or single-phase loads such as electric welding machines, the three-phase currents cannot be completely balanced, and they may even differ greatly. If the electromotive force is too large to a certain extent, it will cause the leakage protector to trip.

b) Poor quality and improper parameter configuration. The construction site did not purchase leakage protection equipment in accordance with the relevant construction specifications and construction plans, and because the quality of the purchased leakage protector itself was low, the actual internal situation did not match the standard parameter standards, just put it into operation The new product used has malfunctioned.

2.Method of using leakage protector scientifically on construction site

While improving the management of construction safety, it is also necessary to strengthen the knowledge training of construction electricians, and the prevention methods adopted must be specified in accordance with the actual situation and construction technology.

1) Avoid external interference. The measures to avoid malfunction caused by lightning overvoltage interference include installing lightning arresters or breakdown gaps on overhead lines, and installing 150mA, 0.2s delay type leakage circuit breakers at the main distribution box, in order to prevent excessive neutral point displacement If the voltage is damaged or the sensitivity of the leakage circuit breaker is reduced, the load should be adjusted to distribute it on the three-phase line as evenly as possible. The cross-sectional area of the conductor shall not be less than the cross-section of the conductor of each phase line.

2) Select and install wiring correctly

a) The selection must be compatible with the line.The performance indicators such as the rated voltage, rated current, and breaking capacity of the leakage switch should be compatible with the line conditions. The withstand voltage of the leakage protector for mains protection and the leakage protector for terminal equipment is different. When a metallic ground fault occurs in the mains of the power supply and the terminal, the fault current generated can be several times different.

b) Implement hierarchical partition protection. The entire construction site is distributed into different leakage protection equipment areas according to majors and different adjacent construction teams. Each protection area must have a complete set of secondary leakage protection facilities, which can improve the entire The sensitivity of the protection area can also reduce the probability of tripping of the protection leakage setting, and reduce the phenomenon of power outage due to faults

c) Strictly distinguish between neutral line and protection line. When the leakage protector is marked with the load side and the power side, the wiring should be installed according to the regulations, and no reverse connection is allowed. The neutral line of the three-level four-wire or four-pole leakage protector should be connected to the leakage protector. The neutral line passing through the leakage protector shall not be used as a protection line, and it cannot be repeatedly grounded or connected to the exposed conductive parts of the equipment. The neutral line on the load side must not be shared with other circuits.

3.Product Description

The common phase-to-phase short circuit can generate a large current, which can be protected by a switch. However, the current leakage caused by human body electric shock and line aging and the ground fault of the equipment are caused by leakage current. The leakage current is generally At 30mA-3A, these values are so small that traditional switches cannot be protected, so a residual current-operated protection device must be used.

The residual current relay is a residual current transformer to detect the residual current, and under specified conditions, when the residual current reaches or exceeds a given value, one or more electrical output circuit contacts in the electrical appliance will open and close. Switch electrical appliances. Here are three common leakage situations.

3.1 High-sensitivity RCD with I△n≤30mA must be used to prevent direct contact and electric shock

3.2 The medium sensitivity RCD with I△n greater than 30mA can be used to prevent indirect contact and electric shock.

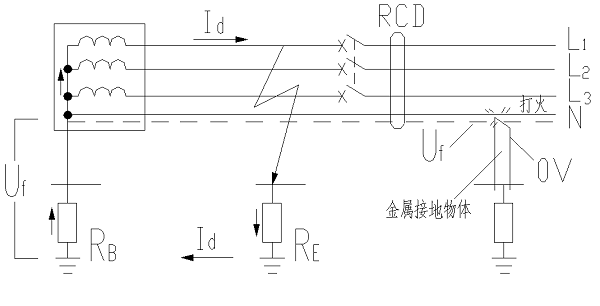

3.3 A 4-pole or 2-pole RCD shall be used for fireproof RCD.

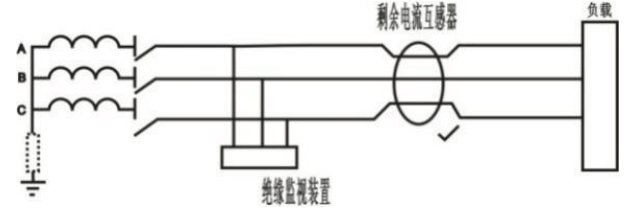

For the IT systems, residual current relays are used as required. In order to prevent the insulation of the system from degrading and as a secondary fault backup protection, according to the wiring type, a protective measure similar to the TT or TN system is adopted. First, an insulation monitoring device should be used to predict a failure.

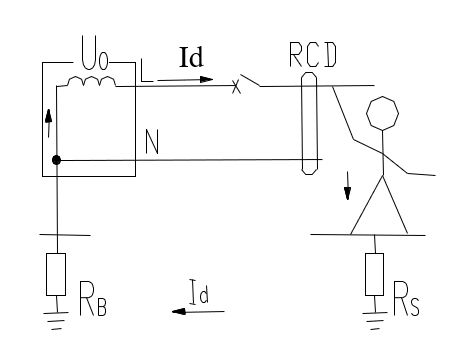

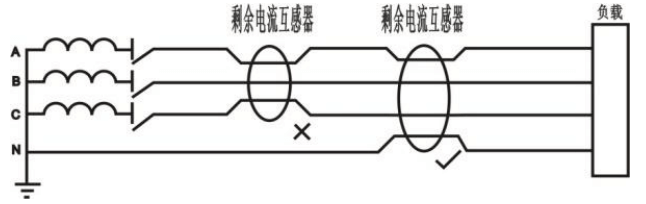

For the TT system, a residual current relay is recommended. Because when a single-phase ground fault occurs, the fault current is very small and difficult to estimate. If the operating current of the switch is not reached, a dangerous voltage will appear on the housing. At this time, the N wire must pass through the residual current transformer.

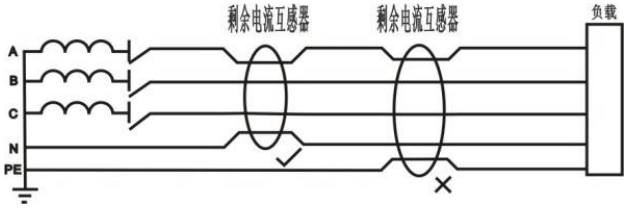

For the TN-S system, a residual current relay can be used. Cut off the fault more quickly and sensitively to improve safety and reliability. At this time, the PE wire must not pass through the transformer, and the N wire must pass through the transformer, and it must not be grounded repeatedly.

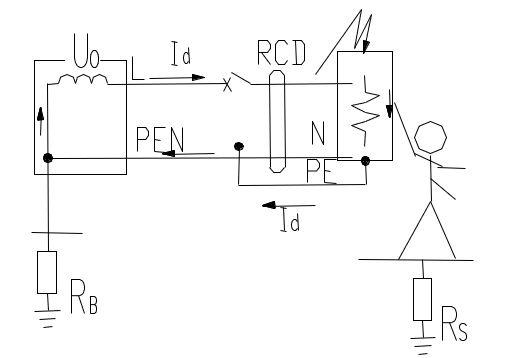

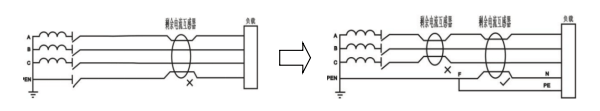

For the TN-C systems, residual current relays cannot be used. Because the PE wire and the N wire are integrated, if the PEN wire is not repeatedly grounded, when the shell is energized, the current in and out of the transformer is equal, and ASJ refuses to move; if the PEN wire is repeatedly grounded, part of the single-phase current will flow into the repeated grounding. After reaching a certain value, ASJ malfunctioned. It is necessary to transform the TN-C system into a TN-C-S system, which is the same as the TN-S system, and then connect the residual current transformer to the TN-S system.

4.Product introduction

Acrel Electric's ASJ series residual current relay can meet the protection of the above-mentioned leakage conditions, and it can be used in conjunction with a remote trip switch to cut off the power supply in time to prevent indirect contact and limit the leakage current. It can also be directly used as a signal relay to monitor power equipment. It is especially suitable for the safety protection of electricity consumption in schools, commercial buildings, factory workshops, bazaars, industrial and mining enterprises, national key fire protection units, smart buildings and communities, subways, petrochemicals, telecommunications and national defense departments.

ASJ series products mainly have two installation methods. ASJ10 series are rail-mounted installations. The appearance and functions are shown in the following table:

|

Model |

Type |

Main function |

Functional Difference |

|

1. Residual current measurement 2. Over-limit alarm 3. The rated residual operating current can be set 4. The limit non-driving time can be set 5. Two sets of relay output 6. With local/remote test/reset function |

1. AC type residual current measurement 2. Current limit alarm indication |

||

|

1. A-type residual current measurement 2. Current percentage bar display |

|||

|

1. A-type residual current measurement 2. Segment LCD display 3. Transformer disconnection alarm 4. Pre-alarm value can be set, return value can be set 5. 25 event records |

ASJ20 series are panel mounted, the appearance and functions are shown in the following table:

|

Model |

Type |

Main Function |

Functional Difference |

|

1. Residual current measurement 2. Over-limit alarm 3. The rated residual operating current can be set 4. The limit non-driving time can be set 5. Two sets of relay output 6. With local/remote test/reset function |

1. AC type residual current measurement 2. Current limit alarm indication |

||

|

1. A-type residual current measurement 2. Current percentage bar display |

Among them, the difference between AC type and A type residual current relay is: AC type residual current relay is a residual current relay that can ensure the tripping of the residual sinusoidal alternating current that is suddenly applied or slowly rising, and it mainly monitors sinusoidal alternating current signals. Type A residual current relay is a residual current relay that can ensure the tripping of residual sinusoidal alternating current and residual pulsating direct current that is applied suddenly or slowly, and mainly monitors sinusoidal alternating current signals and pulsed direct current signals.

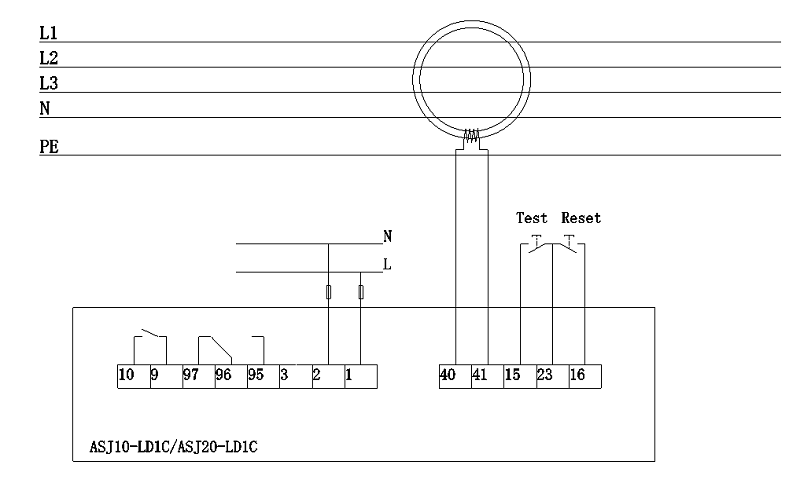

The specific wiring terminals and typical wiring of the instrument are as follows:

5.Conclusion

The leakage protection device can prevent the human body from unconsciously contacting the energized equipment and causing electric shock, which can effectively reduce the damage caused, and has a good preventive effect on electrical fires caused by arc grounding. ASJ series residual current relay products can monitor the leakage current in the line. When the leakage current reaches or exceeds the set value, the internal relay will act to issue an alarm, and can be linked with the circuit breaker switch to quickly cut off the line to ensure line safety.

References

[1] Rui Liang. Analysis of the cause of frequent tripping of the leakage protector on the construction site[J]. China Packaging Science and Technology Expo, 2011, 000(020):277-277.

[2] Enterprise Microgrid Design and Application Manual. 2020.6

[3] Fanji Meng. Problems and solutions in the use of leakage protectors in construction sites[J]. Building Safety, 2001, 06:25-26.

[4] Ping Yuan. Talking about the application of leakage protection in electrical safety [J]. China High-tech Zone, 2017(23):130-131.

[5] Guanghai Liu. Application of Leakage Protector in Elevator Installation Construction Site[J]. China Elevator, 2005, 016(001): 48-51.