Abstract: With the further acceleration of my country’s economic development, people’s living standards have also been continuously improved, and residents’ electricity consumption has been continuously increased. While various household appliances have facilitated people’s lives, they have also improved their lives to a certain extent. Life has also produced greater hidden dangers. In building electrical engineering, if there is a leakage problem, it will affect people's daily life and threaten people's lives. Therefore, it is necessary to adopt leakage protection technology and add leakage protection devices to the electrical engineering system to calmly and effectively reduce the chance of electric shock for construction workers.

Keywords: electric leakage; construction; electric shock

0.Overview

For the electrical construction of buildings, there are many factors that can cause unsafe electrical construction. In summary, they mainly include: For the threading project, the thin conduit and the large number of wires result in a small margin in the pipe and insufficient heat dissipation surface. In addition, the technical quality of the construction personnel is low, and the construction cannot be carried out according to the drawings. This hazard is to accelerate the aging speed of the wire insulation layer and reduce the service life of the project.

The corrosive agent was not wiped clean, the switching process didn’t cut off the phase wire, and even the phase wire was connected to the screw thread post of the lamp cap. Socket installation interchanges the position of the phase wire and the neutral wire, and the wiring problems of the phase wire on the upper and the neutral wire are common safety problems in the wiring work. Many construction workers are prone to paralysis. In catheter laying facilities, the nozzles of metal catheters are not treated, leaving many burrs at the nozzles. These metal burrs are a big safety hazard: these burrs during threading construction It is easy to cut the insulation layer of the wire, and the consequences are unimaginable.

Once a problem occurs, the lighter will cause a short circuit and the power will be difficult to repair, and the severer may cause a fire. During the construction of the lightning protection system. The methods of down-conducting are different. Some use galvanized round steel, and some use the four main reinforcements of the structural column to lay along the wall or inside the column. If the welding is missed during the construction, it will also leave a big safety hazard. The consequences are: missed or missed welding of a round steel, it is very likely that the down conductor will lose its due role, and the lightning protection system will not be able to perform Normal function.

1.Principles of application of leakage protection technology in building electrical engineering

1) In terms of the principle of grounding protection

The neutral point of the low-voltage system of building electrical engineering is generally not grounded, so during the normal operation of the system, the metal shell of the electrical equipment must be grounded, and the metal shell of the power supply equipment must also be grounded. The specific content includes the following aspects: first, portable electrical appliances, mobile electrical appliances, metal bases, housings, voltage transformers and other electrical equipment, transmission equipment must be grounded; second, gasoline, diesel and other metal tanks. The body shell must be grounded; third, in the construction site, elevator tracks, scaffolds, hoisting jib cranes, masts, etc. with a height of more than 20 cm must also be grounded; fourth, power distribution boxes and power distribution panels, welders’ work platforms, etc. must also be grounded. Fifth, in the construction site, two or more grounding points need to be set on electric hoists, gantry cranes, tower cranes and other tracks. Especially for track joints, electrical connection processing must be carried out, and the resistance of the node must be controlled within 4 ohms. If there is a grounding slider in the track, it is necessary to effectively connect the grounding slider to the track through a connecting wire. Sixth, the metal shells and brackets of electrical equipment on line poles must be grounded.

2) In terms of the principle of zero protection

In the normal process of electrical construction of buildings, the uncharged exposed parts of some electrical equipment also need to be zero-connected protection, including the following aspects: First, the metal frame of the power distribution panel and control panel needs to be zero-connected protection; Second, transmission facilities such as electrical equipment must be protected against zero connection; third, metal casings such as transformers, generators, lighting tools, power tools, and capacitor metal casings must also be protected against zero connection. Fourth, the metal brackets, switch metal shells, and capacitor metal shells in the line poles must also be connected to zero protection; Sixth, the metal shells of the equipment in the electrical room of the construction site, the metal doors of the live parts, the railings also need to be connected Zero-protection.

3) Principles of building electrical installation and construction cooperation

In the process of building construction, construction installation personnel and construction personnel closely cooperate and cooperate with each other in various procedures and types of work to improve the construction environment, and try best to achieve no damage, no throwing, no damage, and achieve one-time molding construction as much as possible. If it is a single project, it needs to be completed by the civil construction unit and the building electrical installation unit. The civil construction unit prepares the construction procedures item by item, and the two parties cooperate with each other to make a scientific and reasonable construction plan and plan. Professionals such as electrical equipment installation and electricity use are an important part of the entire construction project and play an important role in the construction process. Therefore, when the civil engineering unit specifies the construction schedule, it needs to consider the problems that may arise during the construction process and the related issues of the building electrical installation profession, and reserve enough electrical installation time to create good construction conditions.

2.Modern building electrical leakage protection counter measures

1) Places where leakage protectors need to be installed.

The environment of construction sites is mostly complex, and there are many kinds of building materials used. In some humid equipment operating environments, leakage protection measures need to be installed. The equipment needs to be moved frequently with the development of the building structure. Many power terminals are temporary, and the installation of leakage protectors is often ignored, which seriously threatens the lives of operators. Safety, and the steady progress of the entire project. Electrical equipment near corrosive and flammable materials need to strengthen safety measures. According to the structure of different sites, select accessories with suitable functions. It’s not allowed to stop suddenly during operation. The design of blocking equipment requires reasonable speed, and the placement of alarm devices should be strengthened. The distribution of electrical wires in buildings is complex, and the cross-sections are likely to cause high temperature and fire. In the design of the leakage protection scheme, it is necessary to consider issues such as hawker alarm and ensuring that the emergency lighting system is energized to ensure safe operation, improve the safety quality of the building, and smoothly invest in the entire project Use a good foundation.

2) Selection of the operating current of the leakage protector

The operating current of the leakage protector of a single electrical equipment is four times or more than the measured leakage current during normal operation; the operating current of the leakage protector in the distribution line is greater than 2.5 times of the measured leakage current during normal operation, and at the same time, it’s also necessary to ensure that the leakage current of the electrical equipment with the largest leakage current is 4 times that of the leakage current during normal operation. When protecting the entire network, its operating current should be twice as much as the measured leakage current. At the same time, the rated operating current of the leakage protector must have a certain amount of interference to meet the requirements of the increase in electrical equipment and the decrease in the resistance of the circuit insulation over time. As well as seasonal temperature defenses, the current leakage increases.

3) Application of four-pole and two-pole leakage protector

The criterion for electrical safety and basic requirements is to minimize the number of contacts, poles, and connection points of electrical appliances. The fixed connection point of the circuit and the movable connection of the switch contact, etc., under the influence of various reasons, will cause accidents due to poor conduction. Especially for the neutral wire in the three-phase circuit, the danger caused by its poor conductivity is more serious. This is because when the neutral wire is poorly conductive, the equipment is still running, and hidden dangers are not easy to find. If the three-phase load is seriously unbalanced, this will make the three-phase voltage also tend to be in a serious unbalanced state, and then burn out the single-phase equipment, so it’s necessary to limit the increase of contacts on the neutral line as much as possible.

4) Implementation of equipotential bonding

Equipotential bonding is a method of connecting the protective zero bus and the metal pipes or devices of the building's HVAC pipe, gas main, water main and other metal pipes with wires to balance the potential in the building. This method is especially suitable for flammable and explosive places. For single-phase 220V lines, the leakage protector can only play the role of indirect contact protection. At the same time, it also has the influence of short life, poor contact and other factors caused by the wear of the mechanical parts and the instability of the quality, resulting in hidden dangers such as operation failure. It cannot be used as an effective protective measure alone. Equipotential bonding is still needed to completely eliminate the occurrence of electric sparks and arcs between low-potential metal parts and leakage equipment or electrical circuits, thereby effectively avoiding fires and other safety accident.

5) Issues that should be paid attention to in use of leakage protectors

① Coordination of the rated leakage current of the leakage protector

In the earth leakage protector for on-site electrical load protection, the rated earth leakage current IΔn1 must meet the condition of IΔn1≤30mA; for the earth leakage protector for main or branch line protection, the premise of the rated earth leakage current IΔn2 is IΔn2 ≥1.25IΔn1; The leakage protector for main trunk or main trunk protection, its rated leakage action current IΔn3 is usually 300mA, according to the corresponding standard, the prerequisite is 300mA≥IΔn3≥1.25IΔn2. Therefore, in summary, the operating conditions of the leakage protector can be summarized as 300mA≥IΔn3≥1.25IΔn2, IΔn2≥1.25IΔn1, IΔn1≤30mA.

② Coordination of the rated operating time of the leakage protector

First of all, according to the relevant standards in the " Regulations of the Installation and operation of leakage protector”, he difference in the rated operating time of the upper and lower-level earth-leakage protectors is 0.2s. As a fast type, the rated value of the end-of-life earth-leakage protector is usually less than 0.1s. , And the ratings of the secondary and tertiary leakage protectors have been extended, and their extension values are 0.2s and 0.4s respectively. In addition, the special nature of the inverse time delay of the leakage protector is used. For example, the first stage is 0.1s less than the second stage, and the third stage must add 0.2s. Finally, if the earth-leakage protector selected by the construction site is of inverse time limit type, you can use the current Japanese standard for use as a reference. If the leakage current is IΔn, the action time is between 0.2 and 1s; if the leakage current is 1.4IΔn, the action time is between 0.1s and 0.5s; if the leakage current is 4.4IΔn, the action time is within 0.05s.

3.Product overview

The common phase-to-phase short circuit can generate a large current, which can be protected by a switch. However, the current leakage caused by human body electric shock and line aging and the ground fault of the equipment are caused by leakage current. The leakage current is generally at 30mA-3A, these values are so small that traditional switches can’t protect, so a residual current-operated protection device must be used.

The residual current relay is a residual current transformer to detect the residual current, and under the specified conditions, when the residual current reaches or exceeds a given value, one or more electrical output circuit contacts in the electrical appliance will open and close. Following are three common leakage situations.

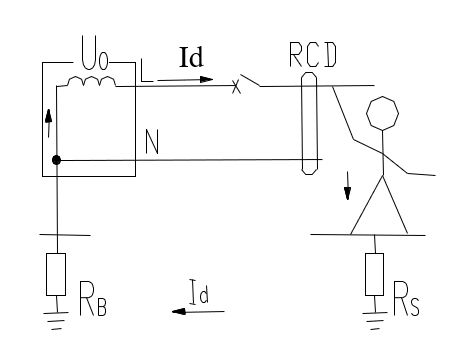

3.1 High-sensitivity RCD with I△n≤30mA must be used to prevent direct contact and electric shock

3.2 The medium sensitivity RCD with I△n greater than 30mA can be used to prevent indirect contact and electric shock.

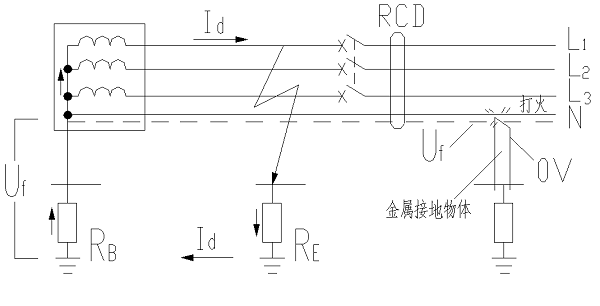

3.3 A 4-pole or 2-pole RCD shall be used for fireproof RCD.

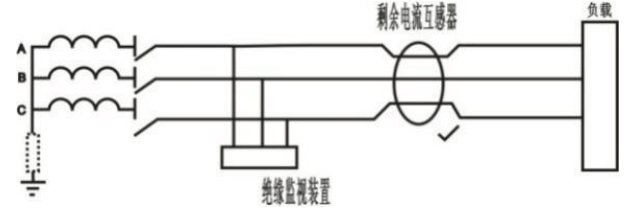

For the IT systems, residual current relays are used as required. In order to prevent the insulation of the system from degrading and as a secondary fault backup protection, according to the wiring type, a protective measure similar to the TT or TN system is adopted. First, an insulation monitoring device should be used to predict a failure.

For the TT system, a residual current relay is recommended. Because when a single-phase ground fault occurs, the fault current is very small and difficult to estimate. If the operating current of the switch is not reached, a dangerous voltage will appear on the housing. At this time, the N wire must pass through the residual current transformer.

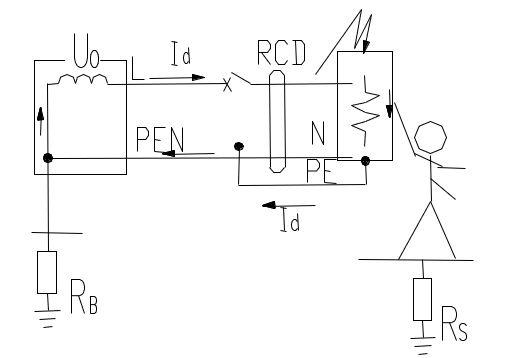

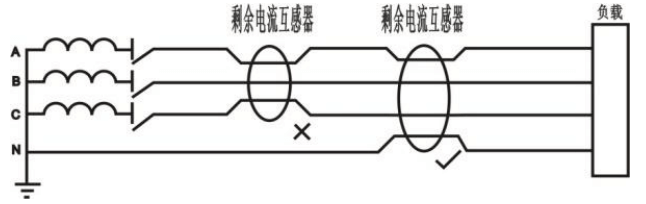

For the TN-S system, a residual current relay can be used. Cut off the fault more quickly and sensitively to improve safety and reliability. At this time, the PE wire must not pass through the transformer, and the N wire must pass through the transformer, and it must not be grounded repeatedly.

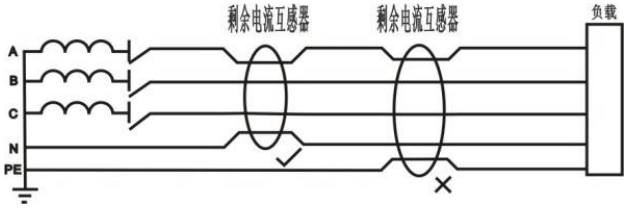

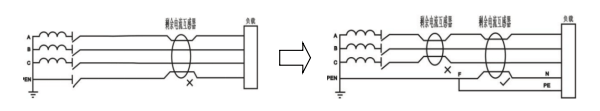

For the TN-C systems, residual current relays cannot be used. Because the PE wire and the N wire are integrated, if the PEN wire is not repeatedly grounded, when the shell is energized, the current in and out of the transformer is equal, and ASJ refuses to move; if the PEN wire is repeatedly grounded, part of the single-phase current will flow into the repeated grounding. After reaching a certain value, ASJ malfunctioned. It is necessary to transform the TN-C system into a TN-C-S system, which is the same as the TN-S system, and then connect the residual current transformer to the TN-S system.

4.Product introduction

Acrel Electric's ASJ series residual current relay can meet the protection of the above-mentioned leakage conditions, and it can be used in conjunction with a remote trip switch to cut off the power supply in time to prevent indirect contact and limit the leakage current. It can also be directly used as a signal relay to monitor power equipment. It is especially suitable for the safety protection of electricity consumption in schools, commercial buildings, factory workshops, bazaars, industrial and mining enterprises, national key fire protection units, smart buildings and communities, subways, petrochemicals, telecommunications and national defense departments.

ASJ series products mainly have two installation methods. ASJ10 series are rail-mounted installations. The appearance and functions are shown in the following table:

|

Model |

Type |

Main function |

Functional Difference |

|

1. Residual current measurement 2. Over-limit alarm 3. The rated residual operating current can be set 4. The limit non-driving time can be set 5. Two sets of relay output 6. With local/remote test/reset function |

1. AC type residual current measurement 2. Current limit alarm indication |

||

|

1. A-type residual current measurement 2. Current percentage bar display |

|||

|

1. A-type residual current measurement 2. Segment LCD display 3. Transformer disconnection alarm 4. Pre-alarm value can be set, return value can be set 5. 25 event records |

ASJ20 series are panel mounted, the appearance and functions are shown in the following table:

|

Model |

Type |

Main Function |

Functional Difference |

|

1. Residual current measurement 2. Over-limit alarm 3. The rated residual operating current can be set 4. The limit non-driving time can be set 5. Two sets of relay output 6. With local/remote test/reset function |

1. AC type residual current measurement 2. Current limit alarm indication |

||

|

1. A-type residual current measurement 2. Current percentage bar display |

Among them, the difference between AC type and A type residual current relay is: AC type residual current relay is a residual current relay that can ensure the tripping of the residual sinusoidal alternating current that is suddenly applied or slowly rising, and it mainly monitors sinusoidal alternating current signals. Type A residual current relay is a residual current relay that can ensure the tripping of residual sinusoidal alternating current and residual pulsating direct current that is applied suddenly or slowly, and mainly monitors sinusoidal alternating current signals and pulsed direct current signals.

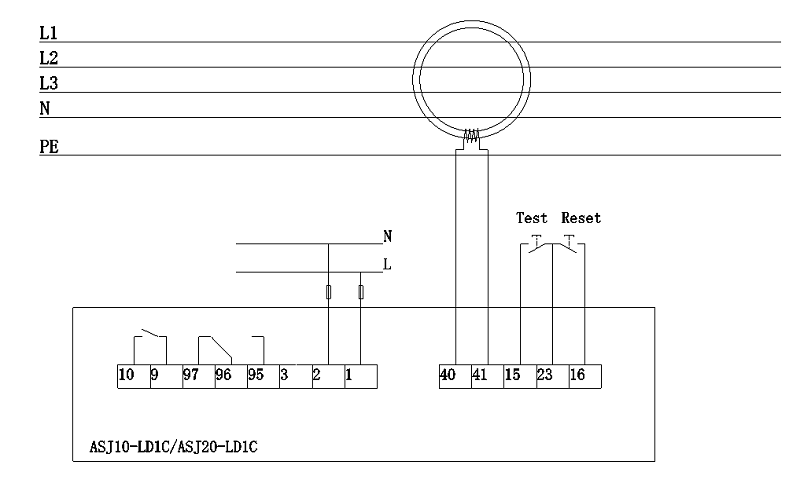

The specific wiring terminals and typical wiring of the instrument are as follows:

5.Conclusion

In modern building electrical, the use of leakage protectors can effectively prevent residents from getting an electric shock, and at the same time can remind users to take necessary protective measures in time. ASJ series residual current relay products can monitor the leakage current in the circuit, when the leakage current reaches or exceeds

References

[1] Fei Song. Research on Leakage Protection Technology in Building Electrical Engineering[J]. Building Materials Technology and Application, 2016, 000(003): 14-16.

[2] Enterprise Microgrid Design and Application Manual. 2020.6

[3] Kai Hu. Analysis of leakage protection technology in the construction of electrical engineering of buildings[J]. Doors and Windows, 2017(2).

[4]Ping Yuan. Talking about the application of leakage protection in electrical safety[J]. China High-tech Zone, 2017(23):130-131.

[5] Zhiyong Zhao,etc. Talking about the leakage protection technology in the construction of electrical engineering [J]. Science and Technology Vision, 2017.